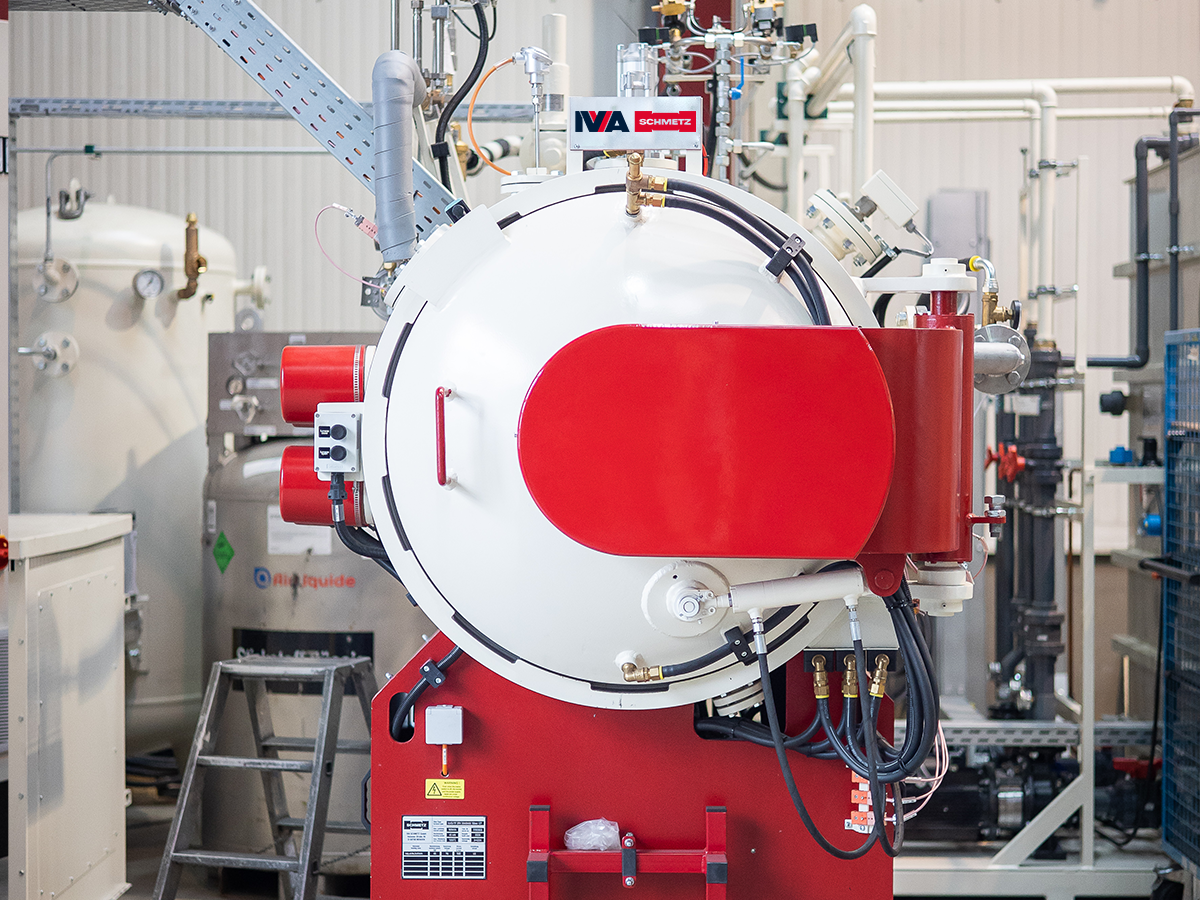

Vertical High-Temperature Vacuum Furnace

Our vertical bottom loading vacuum furnace with a round heating chamber is ideal for high-temperature processes such as hardening, brazing, and sintering.

This furnace is particularly well-suited for large, rotationally symmetrical components such as turbine parts and larger dies. Alternatively, we also offer a space-saving layout with an external heat exchanger or a pit-type furnace variant.

Advantages:

Efficient Heat Distribution:

The round heating chamber ensures uniform temperature distribution, resulting in consistent and high-quality outcomes.

Versatility:

The furnace is ideal for various high-temperature processes such as hardening, brazing, and sintering.

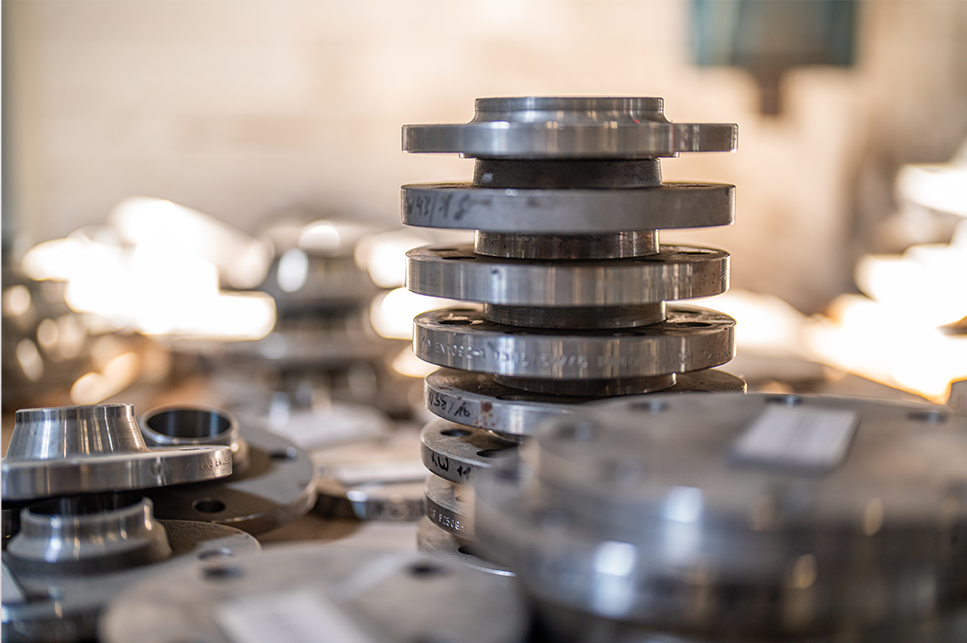

Suitable for large Components:

Especially well-suited for large, rotationally symmetrical parts such as turbine components or pellet dies.

Alternative Design Options:

In addition to the classic lift-lower design, the furnace can be adapted to your available space with an external heat exchanger or a pit-type configuration. A shaft furnace version is also available, offering additional flexibility in furnace selection.

Technical Details

DIMENSIONS

Diameter: 1,200 - 3,000 mm

Height: 1,200 - 3,000 mm

BATCH WEIGHT

Max. 5,000 kg

GAS SUPPLY

• Nitrogen

• Argon

• Helium

• Forming gases

• Gas mixtures

CONTROL

• Intrinsically safe, fail-safe PLC

• Without operator intervention & maximum reliability

• High-performance switching and control systems with freely programmable control

• On request with process control system for convenient storage and documentation of all relevant batch data

NORMS AND STANDARDS:

- Pressure Equipment Directives: AD2000, SELO, ASME, KGS, etc.

- AMS2750 compliant

- GM & NADCA Requirements

COOLING SYSTEM

Cooling gas pressure:

0,9 - 15 bar (abs.)

TEMPERATURE

Max. 1,600 °C

HEAT TREATMENT PROCESS

• Tempering

• Annealing

• Hardening

• Soldering

• Sintering

ADDITIONAL OPTIONS

• 1R: One direction cooling system

• RD: Radial cooling gas stream via 360°

oriented nozzles

• RA: Two-directional cooling gas stream

via radial and axial cooling

• M-ROTOR: Radial or axial cooling gas stream

and rotating bottom for a 360 rotation

of the load • FUTUR: Convective heating under protective gas atmosphere

*Special customer specifications available upon request.

INQUIRY

We would be happy to provide you with a personalized quotation according to your needs.

You can reach us by phone, conveniently by email, or via our contact form.