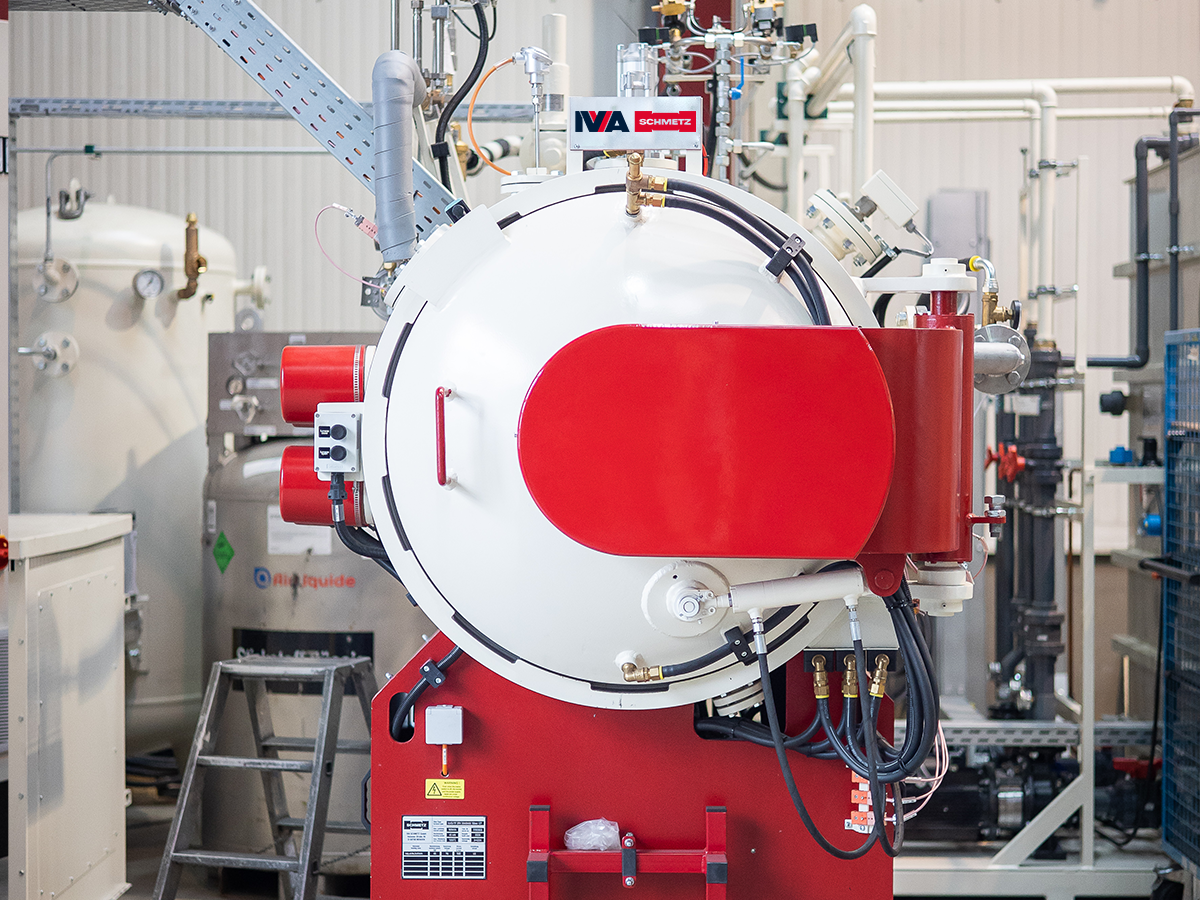

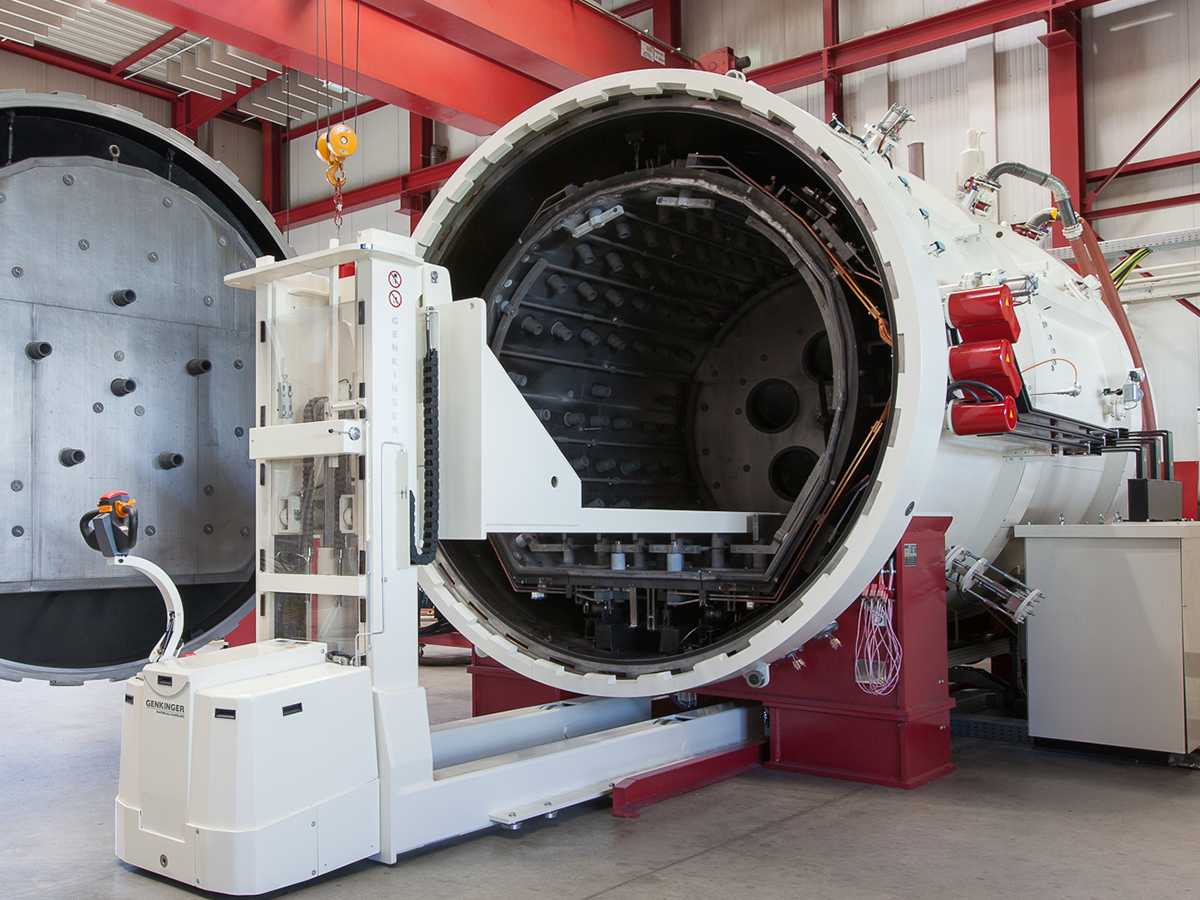

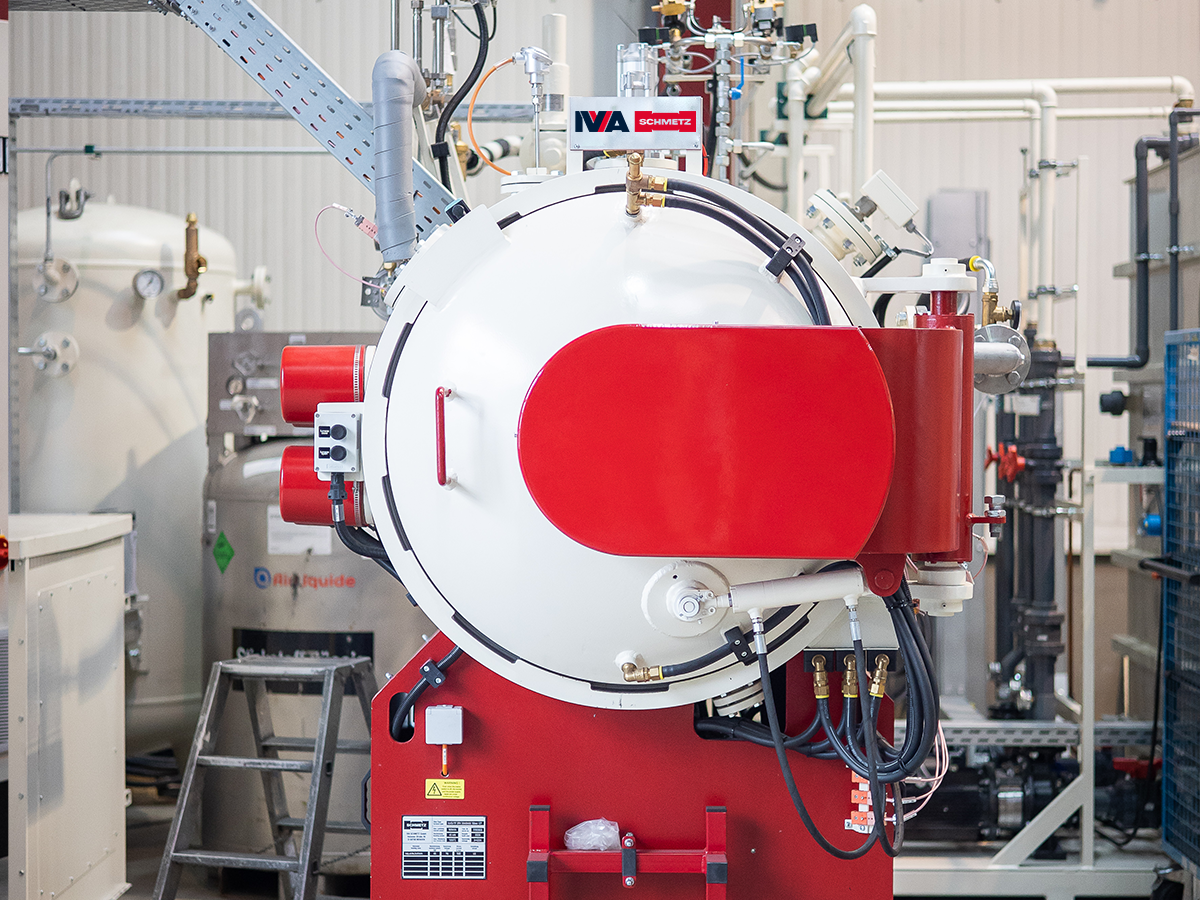

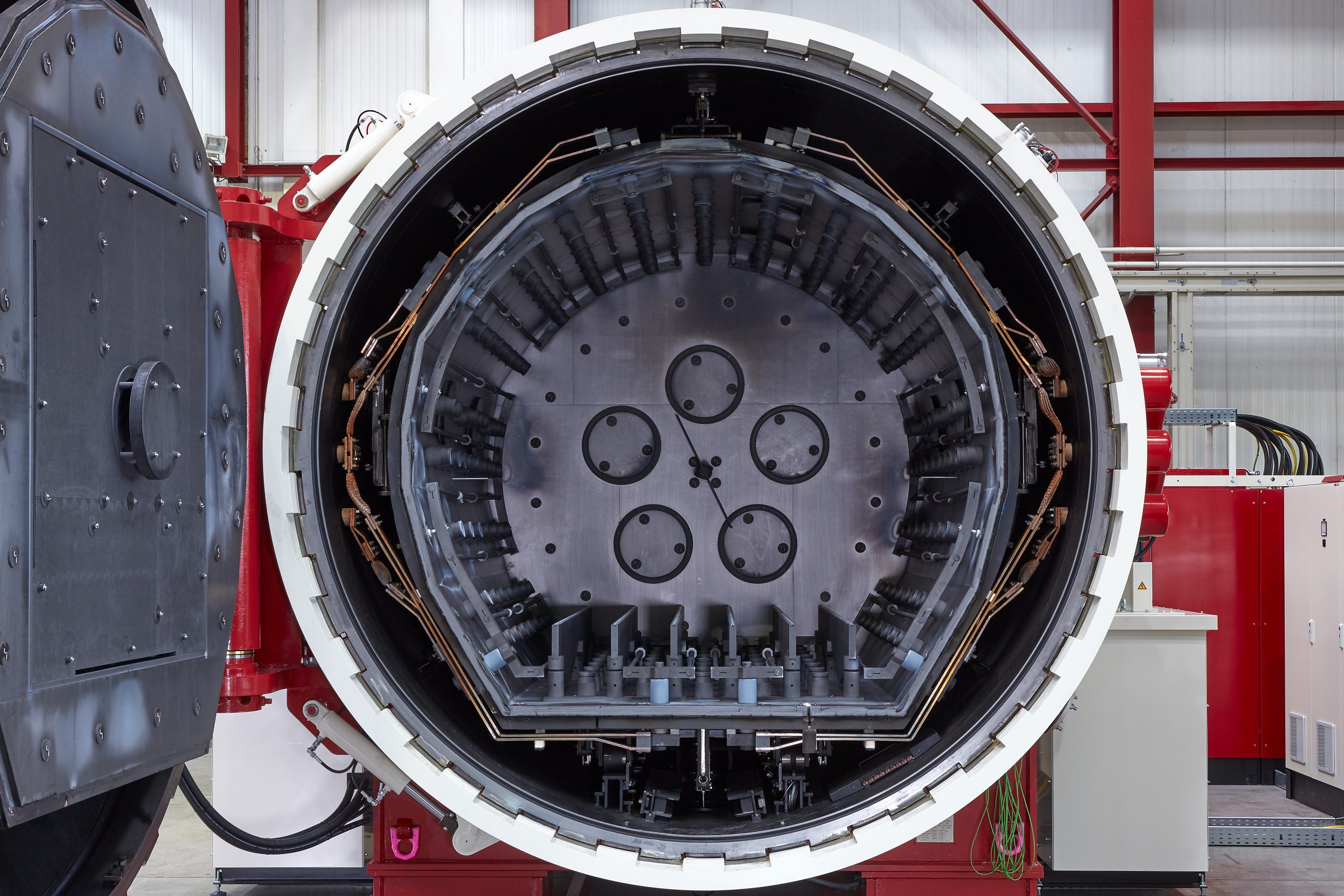

Horizontal Vacuum Furnaces – the All-rounder

Our vacuum chamber furnaces with round or square heating chambers made of graphite or molybdenum for high-temperature processes are the all-rounder for the heat treatment of various components in a wide variety of component sizes in small or large series.

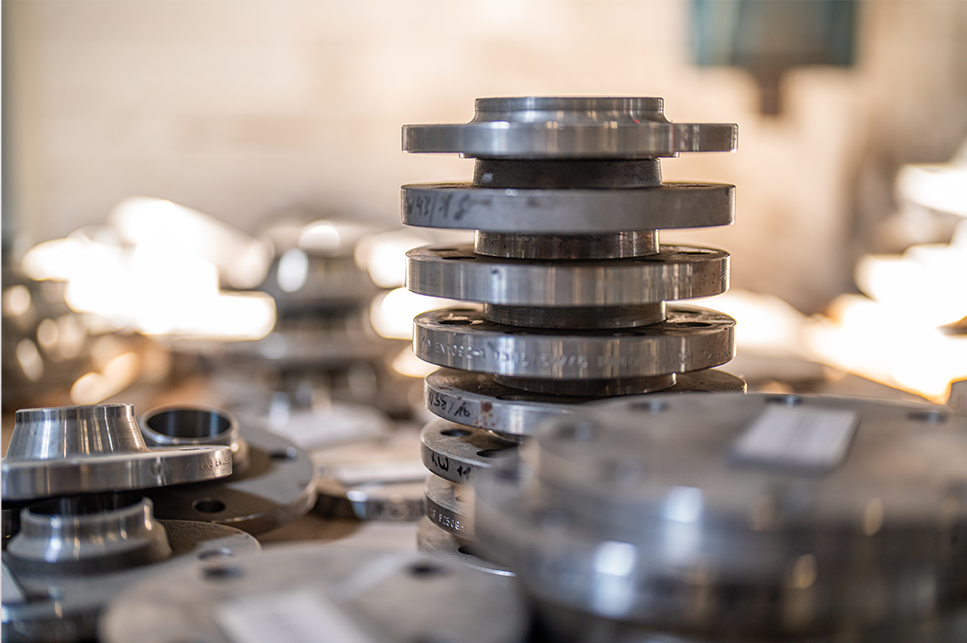

Whether for the heat treatment of additive manufactured implants made of titanium alloys for medical technology as well as for the hardening of huge dies for the automotive industry or for brazing of plate heat exchangers, the horizontal vacuum chamber furnace is the universal system for almost all tasks and applications.

With our furnace configurator, you can design your industrial furnace according to your individual requirements – quickly, intuitively and efficiently.

Technical Details

DIMENSIONS

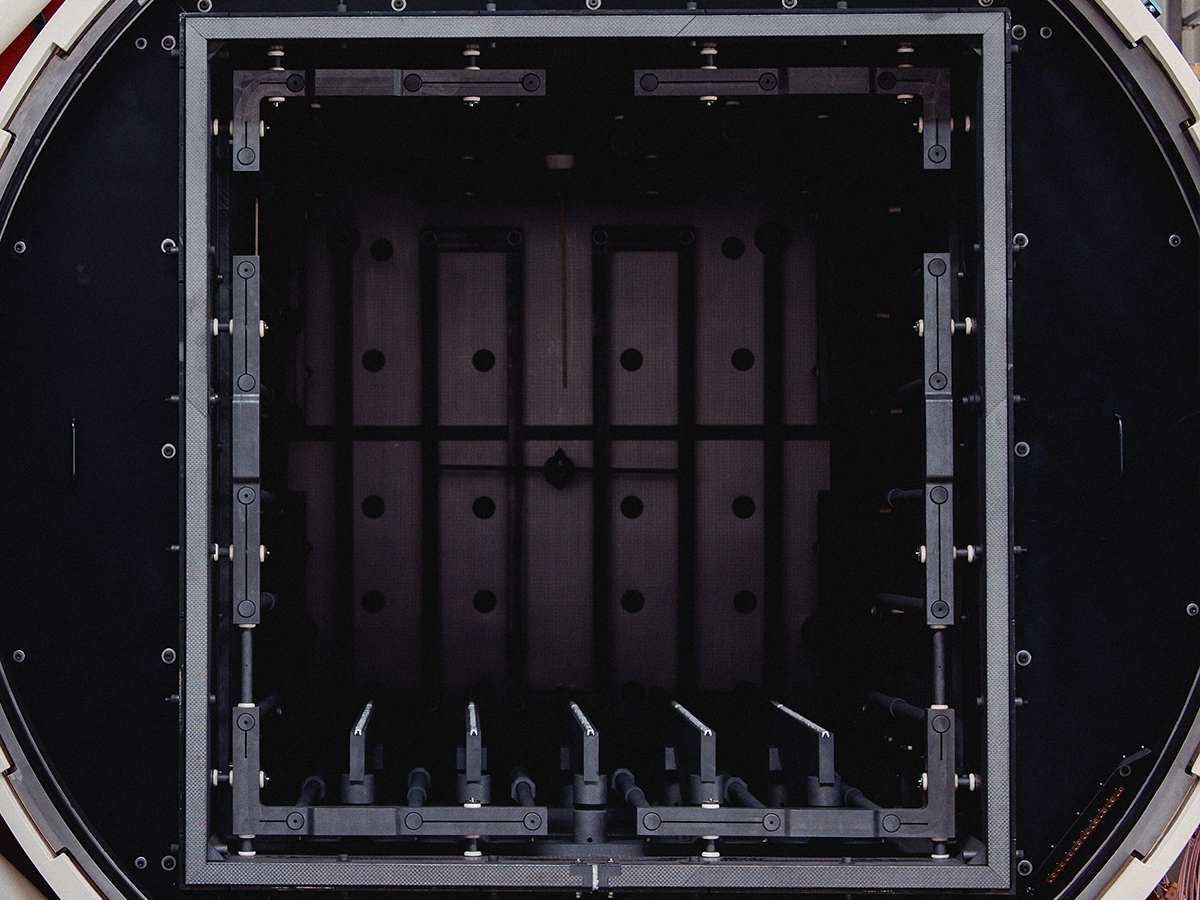

Length: 300 - 3,000 mm

Width: 300 - 1,200 mm

Height: 300 - 1,200 mm

BATCH WEIGHT

from 50 to 15,000 kg

GAS SUPPLY

• Nitrogen

• Argon

• Helium

• Forming gases

CONTROL SYSTEM

- Intrinsically safe, fail-safe PLC

- Operates without operator intervention & offers maximum reliability

- Powerful switching and control systems with freely programmable logic

- Optional process control system for convenient storage and documentation of all relevant batch data

STANDARDS AND REGULATIONS

- Pressure equipment directives: AD2000, SELO, ASME, KGS, etc.

- Compliant with AMS2750

- Meets GM & NADCA requirements

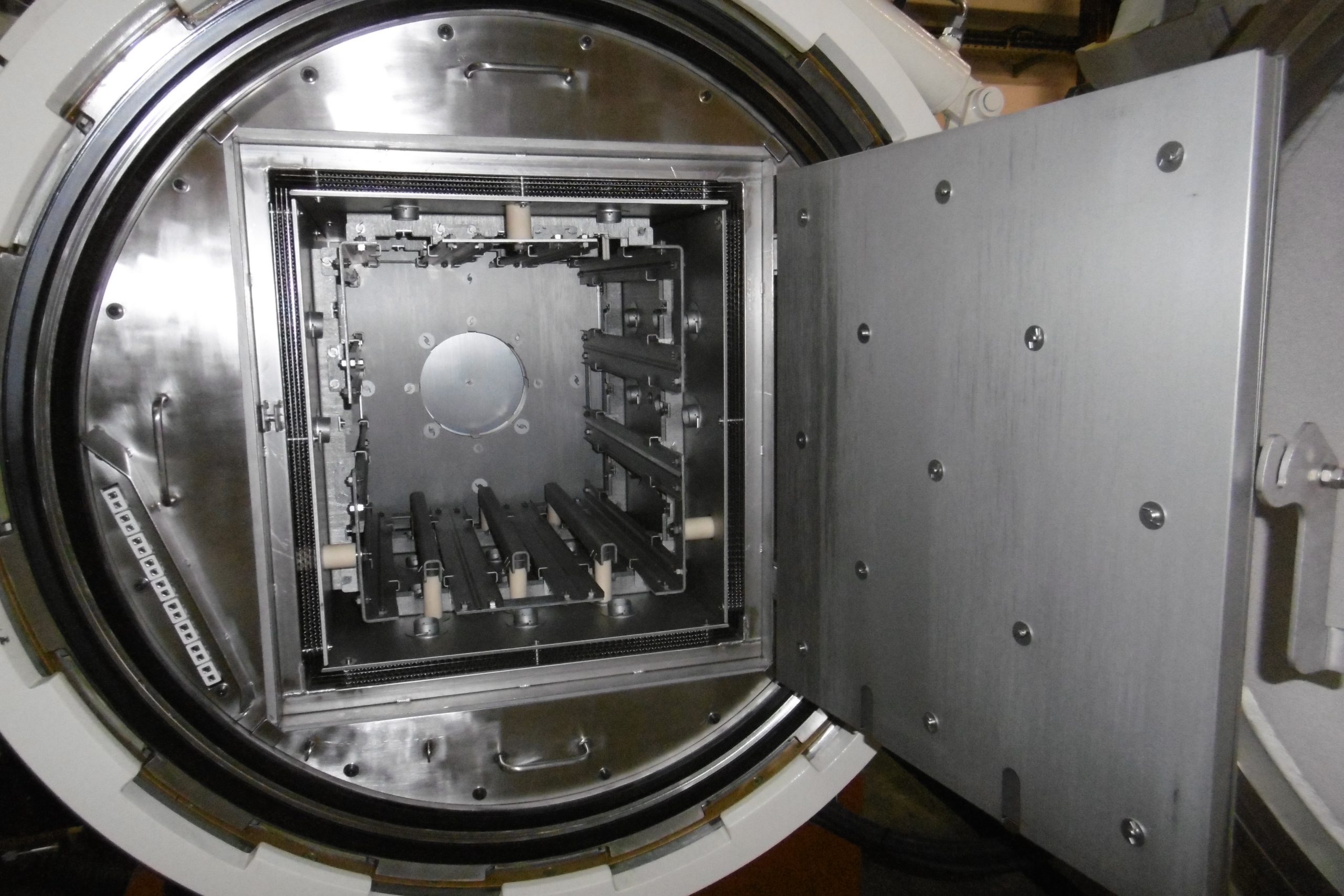

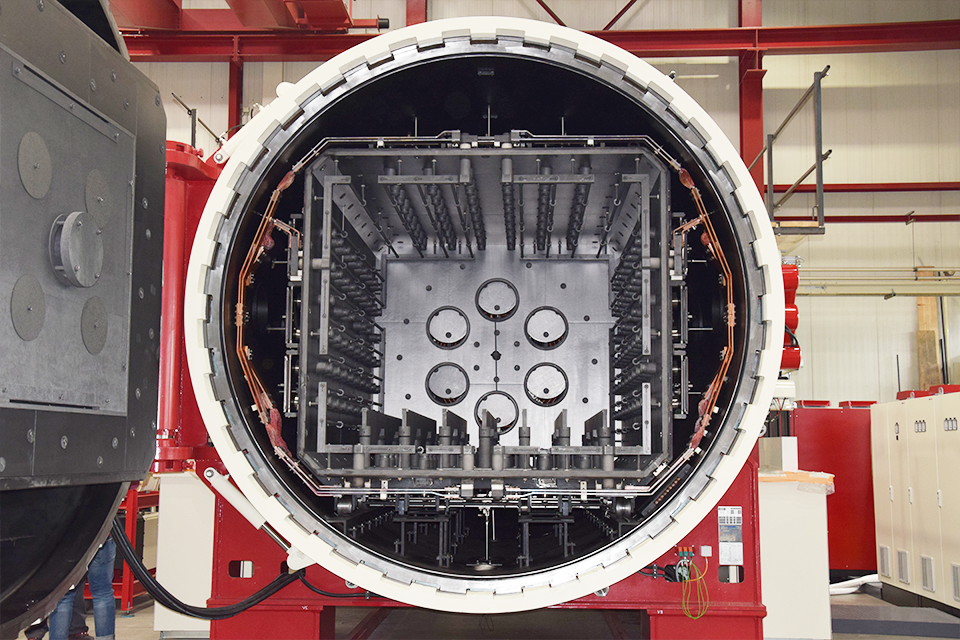

HEATING CHAMBER DESIGN

- Graphite Insulation: High temperature resistance and energy efficiency

- Molybdenum and Stainless Steel Versions: Designed for demanding high vacuum processes

COOLING SYSTEM

Cooling gas pressure:

0.9–15 bar (abs.)

TEMPERATURE

Max. 1,600 °C

HEAT TREATMENT PROCESS • Hardening

• Tempering

• Annealing

• Brazing

• Sintering

• Low-pressure carburizing (LPC)

• Cryogenic cooling (COOL PLUS)

ADDITIONAL FEATURES

- FUTUR: Convective heating under protective gas atmosphere

- 2R: Two-directional cooling with alternating flow direction

- 2x2R: Vertical and/or horizontal cooling from up to four directions with alternating flow direction

- RDPLUS: Cooling gas injection through radially distributed nozzles (for round heating chambers) and optimized gas flow in the bottom area

- 2PLUS: Standard chamber furnace equipped with an additional cooling chamber to double the cooling speed

- COOLPLUS: Integrated, fully automatic deep cooling process down to -145 °C

- eSS: Energy-optimized heating chamber design for up to 10% energy savings

*Special customer specifications available upon request.

INQUIRY

We would be happy to provide you with a personalized quotation according to your needs.

You can reach us by phone, conveniently by email, or via our contact form.