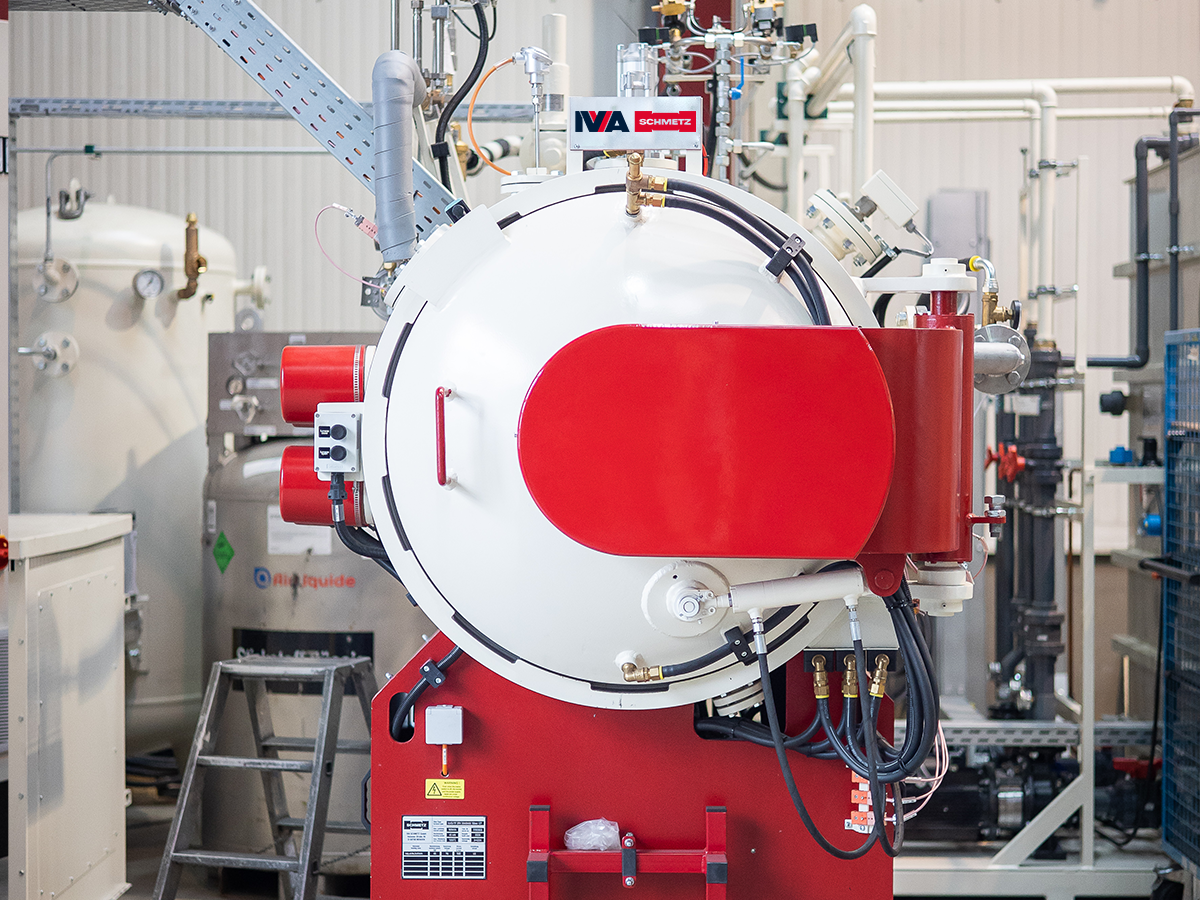

COOL PLUS Sub-zero Integrated, Fully Automatic Gryogenic Cooling

The patented COOL PLUS technology is available for the entire tempering furnace range. This cryogenic treatment is ideal for stainless steels, high-speed steels, and tools and is performed between quenching and tempering cycles.

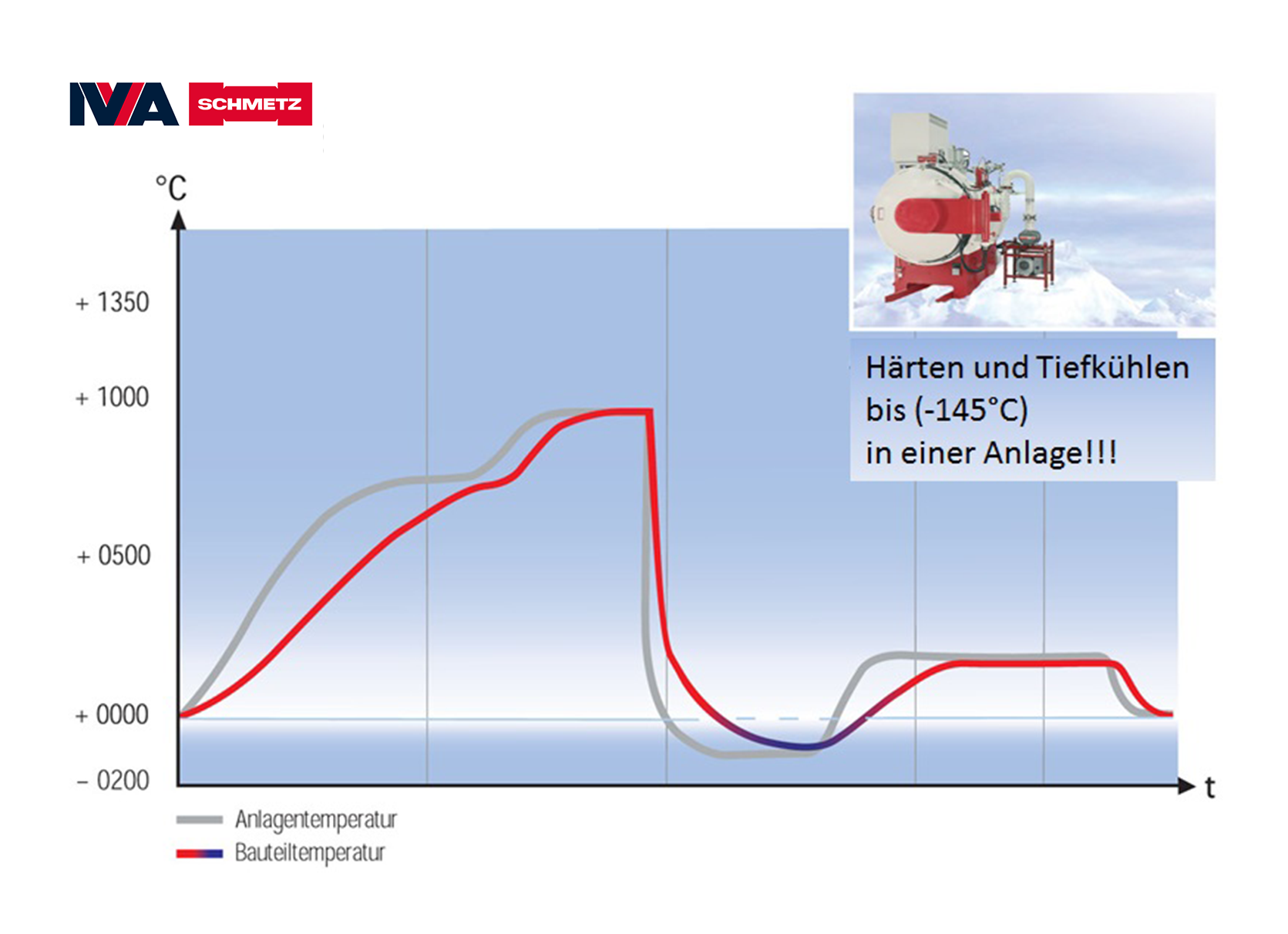

Process:

The injection of liquid nitrogen evaporates into gaseous nitrogen in the heating zone.

Surface temperatures range between -40°C and -120°C.

Fully automated and controlled for perfect reproducibility.

Example:

X20Cr13 steel, quenched at 1035°C and cooled to -100°C, achieves a hardness of 690 HV, compared to 640 HV without cryogenic treatment.

Benefits:

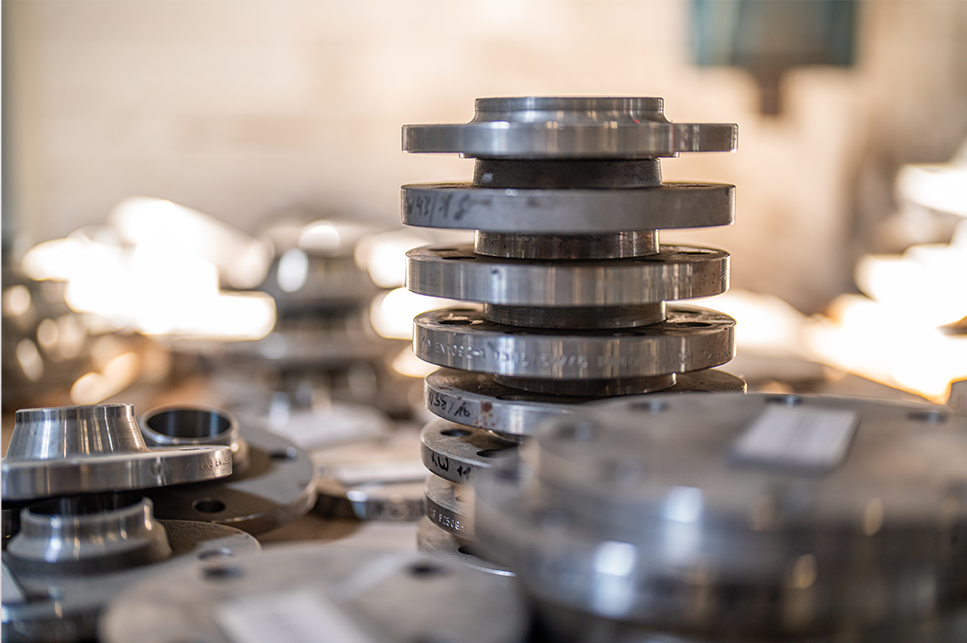

- Increased hardness and dimensional stability: Ideal for components that must remain stable under extreme conditions

- Increased hardness: Significantly increases the hardness of corrosion-resistant steels

- Reduced retained austenite: Improves dimensional stability

- Maintained exceptional gloss: Treated parts retain their optical quality

- Reduced tempering times and costs: Increases efficiency and competitiveness

INQUIRY

We would be happy to provide you with a personalized quote tailored to your needs. You can reach us by phone, conveniently by email, or via our contact form.