We'll take care of it.

For us, you, our customer, are our top priority. From creating customized maintenance plans and questions about processing specific products to general training and system upgrades, we're always there to support you with advice and assistance regarding your system.

Case Studies

Initial Situation

Initial Situation Project Objective

Project Objective Implementation

Implementation Results

Results

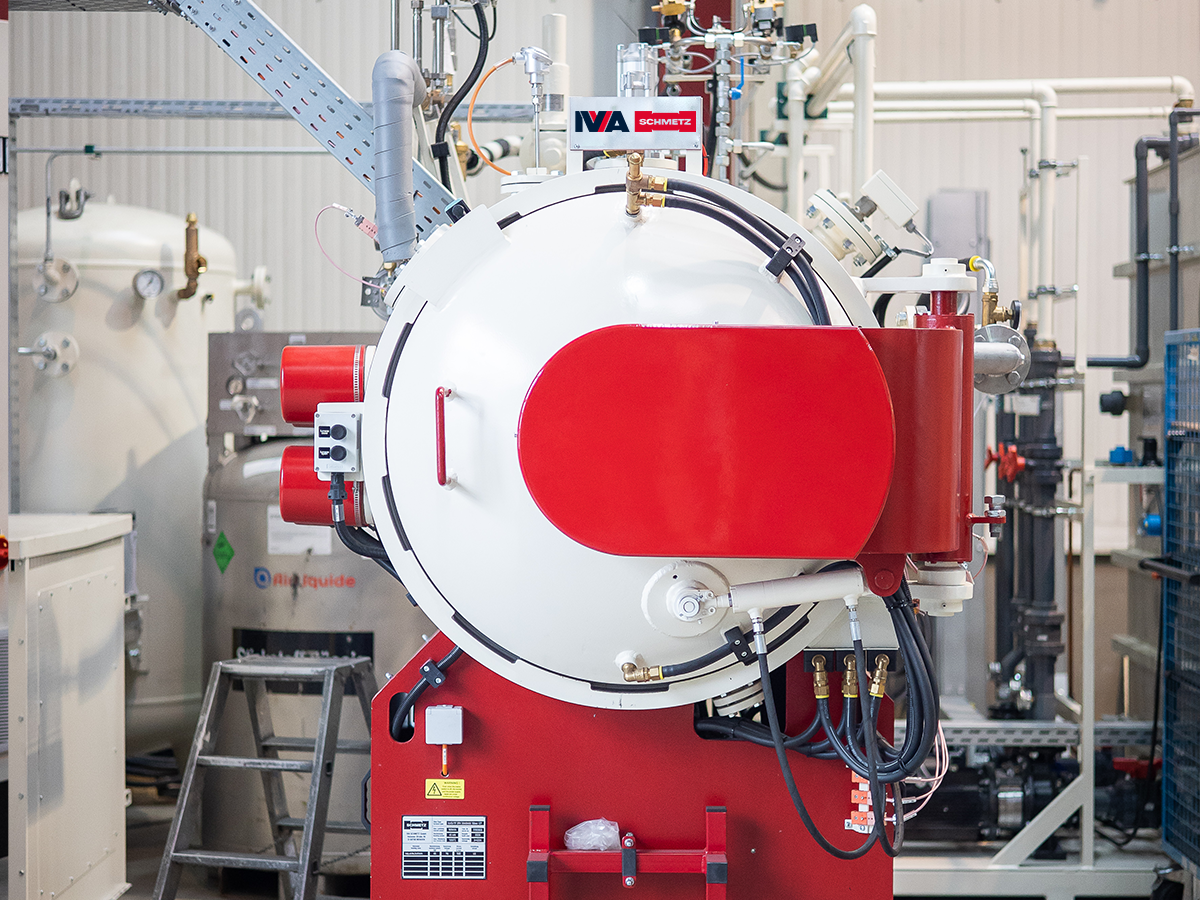

Heating Chamber Smart Repair and Upgrade

At a contract heat treatment company, parts of the heating system and insulation were destroyed due to an accident involving a complex batch, rendering the system inoperable.

Challenge

The system had been certified and commissioned for a customer, so it needed to be brought back into production quickly.

Solution by IVA Schmetz

Smart repair of the existing heating chamber using genuine IVA Schmetz parts and service personnel to quickly get the customer's production up and running again. Subsequently, a new heating chamber was designed and manufactured with optimized gas inlets and surface protection tailored to the customer's applications, which was installed during the next maintenance visit.

Result

The customer's production downtime was reduced to just a few days. In the future, the customer will have a replacement chamber tailored to their application and offering a high degree of production reliability.

Relocation of In-House Heat Treatment Facility

Relocation of In-House Heat Treatment Facility Challenge

Challenge Solution by IVA Schmetz

Solution by IVA Schmetz Result

Result