MULTIBRAND SERVICE

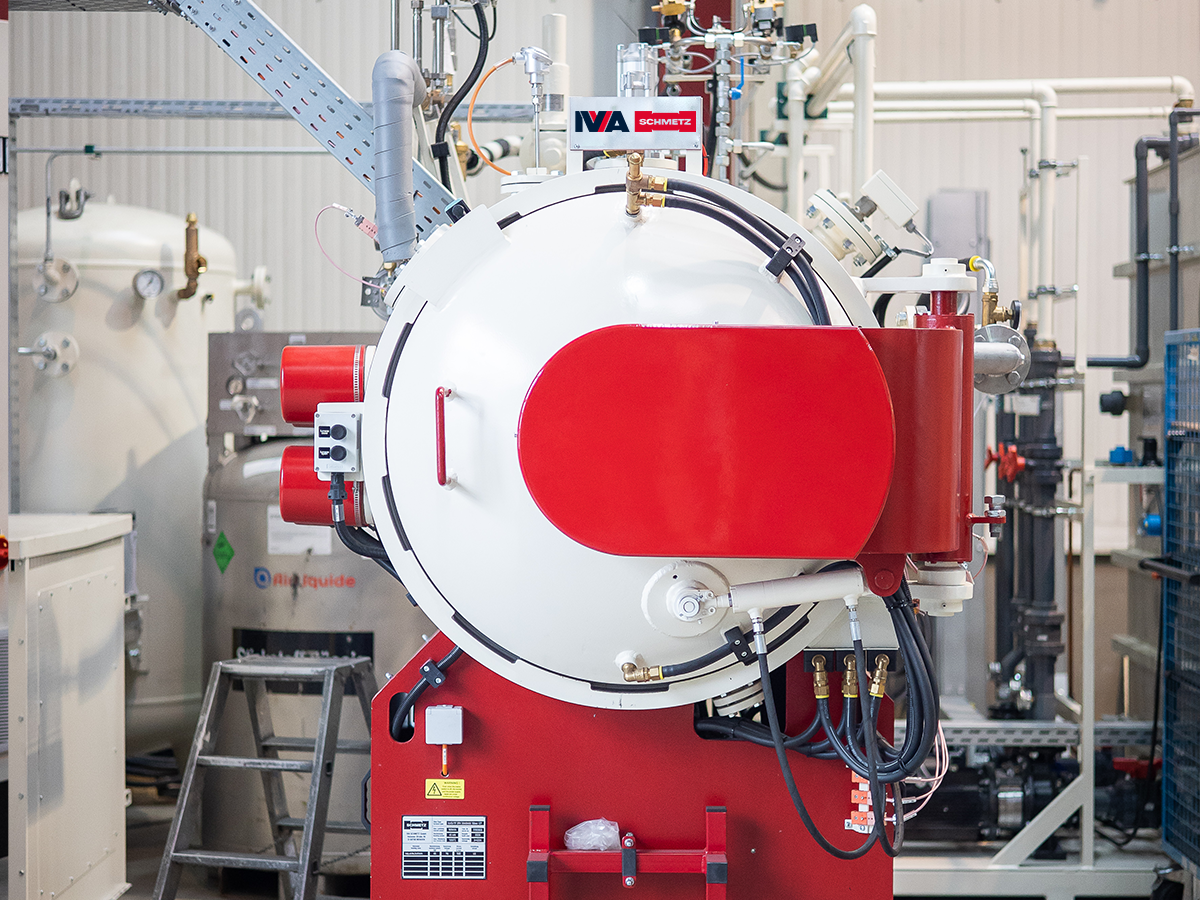

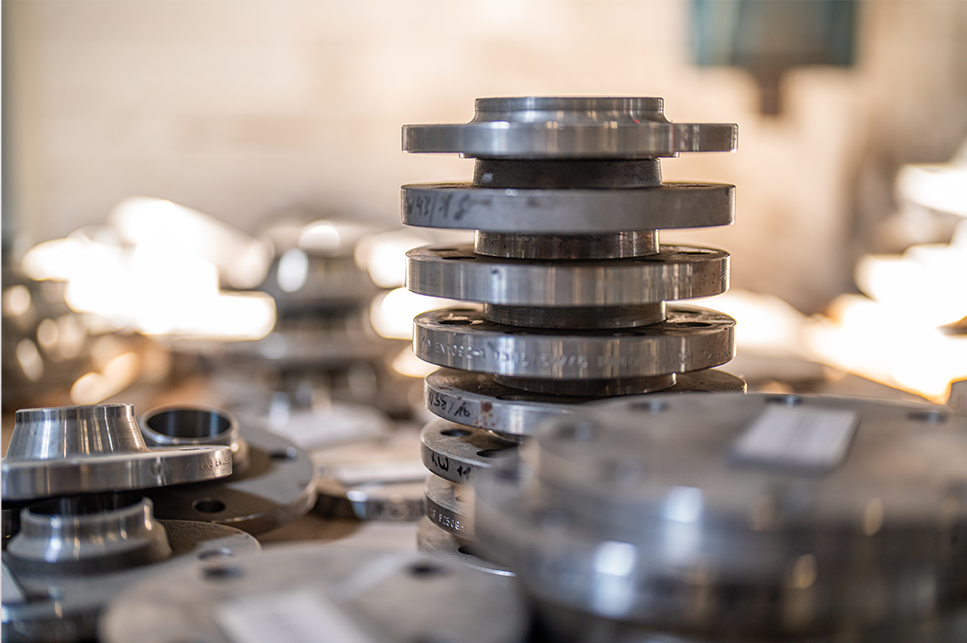

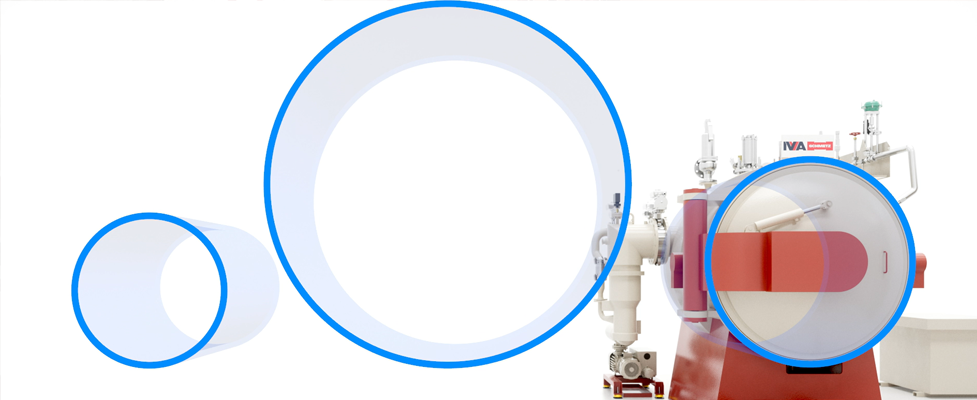

You can rely on IVA SCHMETZ as your experienced multibrand service partner. Our team has many years of expertise in servicing third-party furnace systems and specializes in vacuum and atmosphere technologies. No matter your system’s requirements, our service technicians provide tailored solutions and full support.

We combine the know-how of four leading furnace manufacturers within our group and continuously expand our cross-brand service capabilities. This enables you to optimize your heat treatment processes, extend equipment lifetime, and maximize profitability.

Services

Our multi-brand services cover over 20 different oven types, from manufacturers such as Ipsen, TAV, Aichelin, KGO, WMU, Cieffe and many more.

Datenerfassung & Analyse

Datenerfassung & Analyse Technische Prüfung vor Ort

Technische Prüfung vor Ort Dokumentation & Beratung

Dokumentation & Beratung Gleichmäßigere Temperaturverteilung (±5 °C)

Gleichmäßigere Temperaturverteilung (±5 °C)