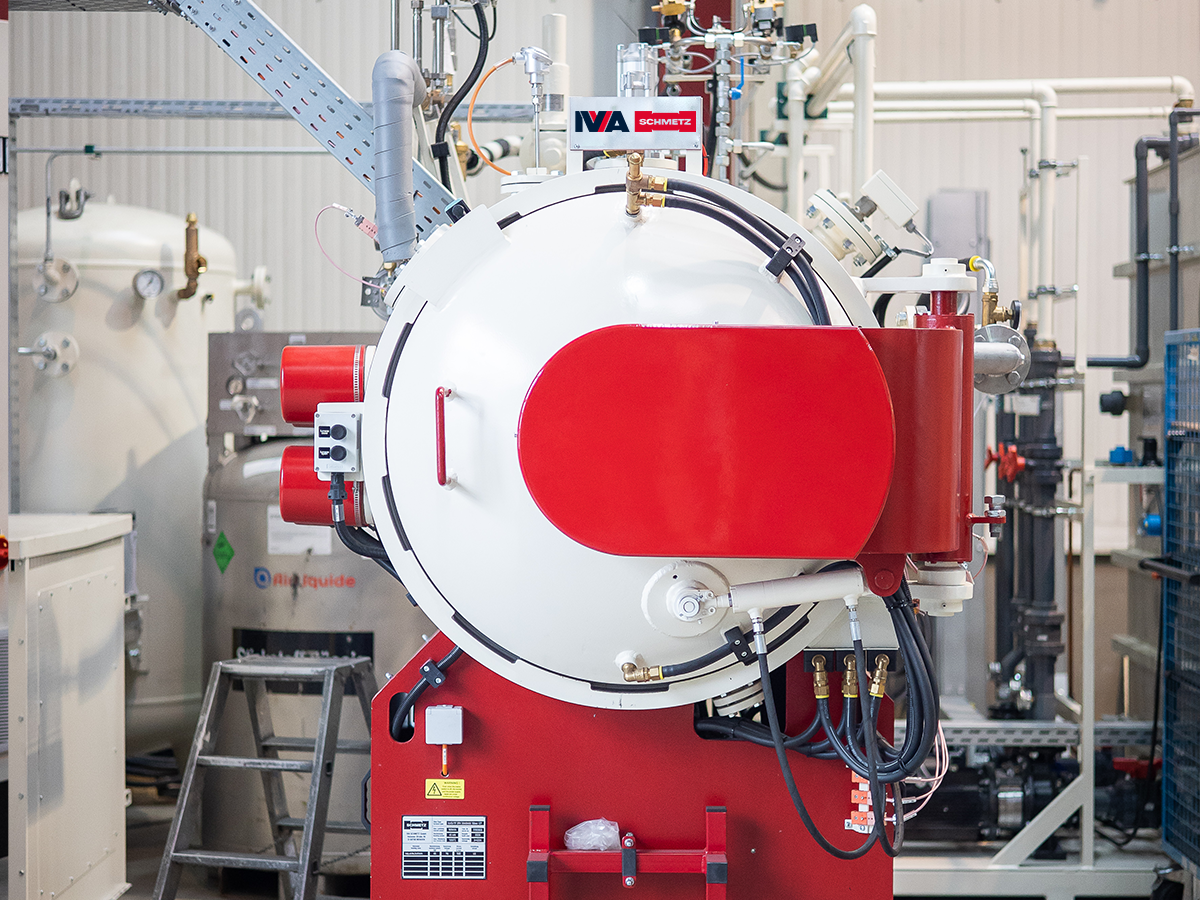

Sealed Quench Furnaces -

Efficient Atmosphere Furnaces

Our universal chamber furnaces offer flexible solutions for a wide range of industrial applications. They are ideal for processes such as hardening, tempering, and annealing under controlled atmospheres.

Key Benefits:

- Energy Efficiency: Reduced energy consumption thanks to advanced insulation materials.

- Versatility: Easily adaptable to various process requirements.

- Reliability: Robust design ensures long service life and consistent performance.

Technical Details

BATCH

Length: 900 – 1,830 mm

Width: 600 – 1,300 mm

Height: 600 – 950 mm

BATCH WEIGHT

Max. 2,500 kg

GAS SUPPLY

• Nitrogen – Methanol

• Nitrogen-hydrogen mixtures (forming gas)

• Endogas

• Ammonia

• Nitrogen

CONTROL

Intrinsically safe, fail-safe PLC

• No operator intervention & highest

reliability

• Powerful switchgear and control systems with freely programmable control

• Exact reproducibility of

heat treatment results

• With process control system on request

COOLING SYSTEM

• Gas cooling in the pre-chamber

• Quenching in an oil bath

TEMPERATURES

Maximum temperature: 1,050 °C

HEAT TREATMENT PROCESSES • • Carburizing

• Case hardening

• Carbonitriding

• Nitriding / Nitrocarburizing

• Hardening under protective gas

• Annealing under protective gas

• Stress relieving

• Pearlitizing

Do you need a quote? Do you have questions?

We would be happy to provide you with a customized quotation according to your needs.

You can reach us by phone, email, or via our contact form.