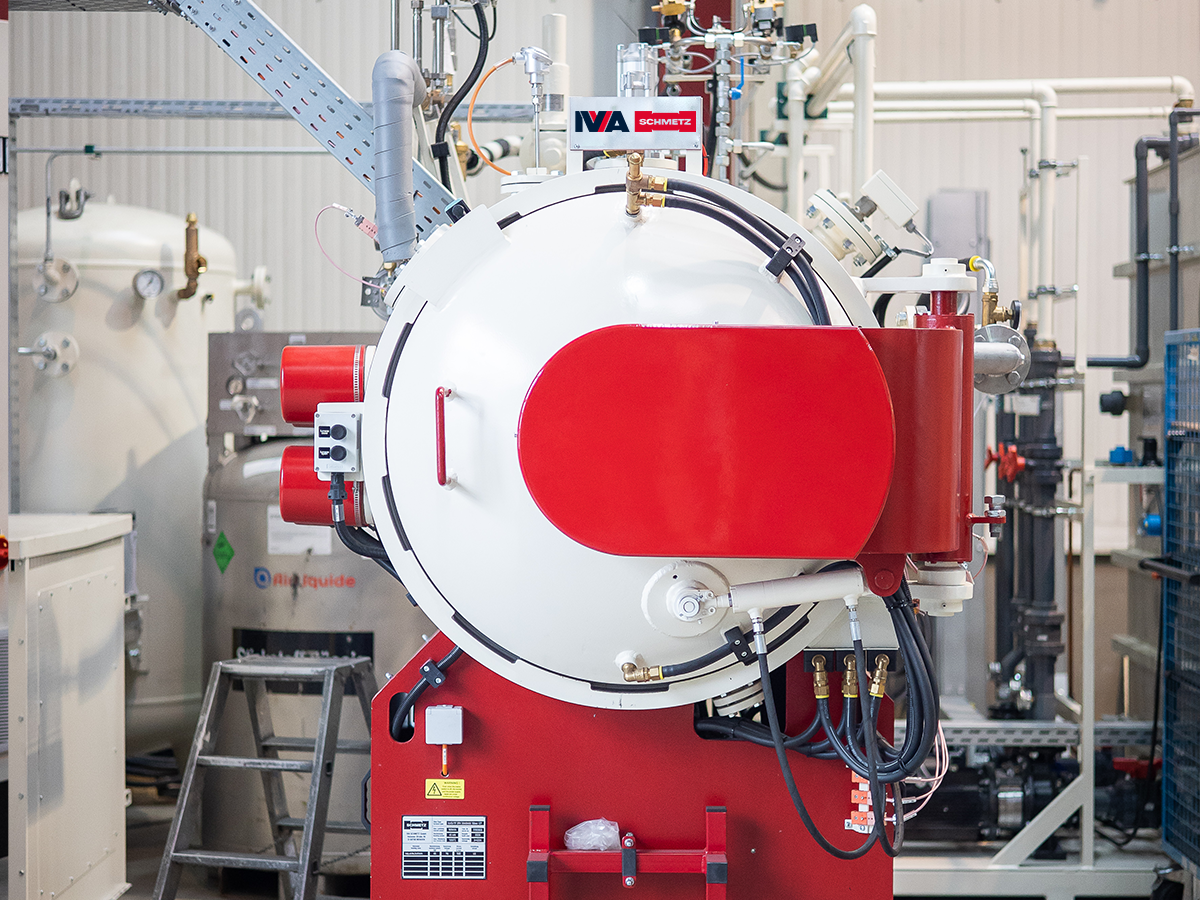

High-quality Retort Furnaces for a Wide Range of Applications

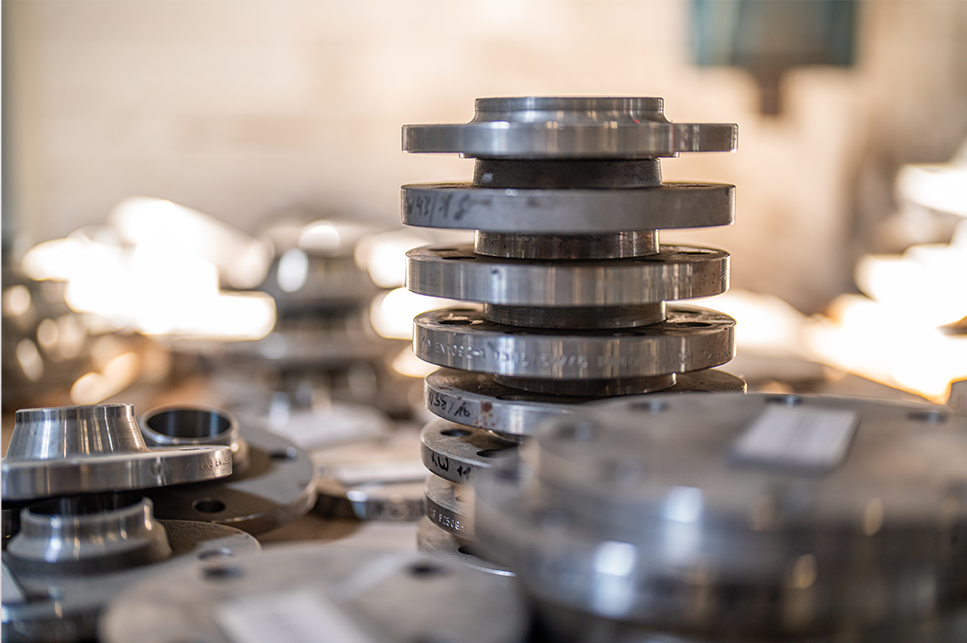

Our retort furnaces are ideal for tempering tools and for various annealing processes such as recrystallization annealing, stress relieving, solution annealing, thermal aging, and precipitation hardening. They are also perfectly suited for thermochemical heat treatment processes like gas nitriding and nitrocarburizing, including corrosion-resistant post-treatment (oxidation).

Our systems are available in electric and gas-fired versions. Each retort is custom-built to meet your specific process requirements.

Technical details

BATCH

Length: 600 – 3,000 mm

Width: 500 – 1,300 mm

Height: 500 – 1,300 mm

BATCH WEIGHT

Max. 6.000 kg

GAS SYPPLY

• Hydrogen

• Nitrogen

• Ammonia

• Cracked gas

• Carbon dioxide

• Nitrogen-hydrogen mixture (forming gas)

CONTROL

• Intrinsically safe, fail-safe PLC

• No operator intervention & highest

reliability

• Powerful switchgear and control systems with freely programmable control

• Exact reproducibility of

heat treatment results

• With process control system on request

COOLING SYSTEM

Indirect cooling via an external cooling fan with air

TEMPERATURES

Maximum temperature: 750 °C

HEAT TREATMENT PROCESSES • • Tempering

• Bright annealing / Annealing

• Post-oxidizing

• Nitriding / Nitrocarburizing

• Normalizing

• Pearlizing

• Pre-oxidizing

ADDITIONAL OPTIONS

• SUBZERO: The charge can

be deep-frozen directly after tempering (down to approx. -100°C)

• DIRECT COOLING: The

furnace atmosphere is cooled down as quickly as possible using an additional, separate heat exchanger

• REKU HEAT: The installation of recuperative burners achieves a 20% reduction in heating gas consumption

• NITROMA: Nitriding index control with

hydrogen analysis • DRY: An additional heat exchanger allows the furnace to be operated

without external cooling water • HIGH: Furnace door can be designed as a lifting gate • LINE: Expansion to complete, fully automatic nitrocarburizing lines

Do you need a quote? Do you have questions?

We would be happy to provide you with a personalized quotation according to your needs.

You can reach us by phone, conveniently by email, or via our contact form.